Hot water returning sterilizer(auto clave)

Home > Machinery > Hot Water Steam Sterilization Tunnel Machine

> Hot water returning sterilizer(auto clave)

Hot water returning sterilizer(auto clave)

Specifications and inspection data followed by manufacturing

The hot water tank and the sterilization tank are the first pressure vessels, which are manufactured, tested and accepted according to the national standard GB150-1998 "Steel Pressure Vessel" and the former Ministry of Labor "Pressure Vessel Safety Technology Supervision Regulations".

Welding is carried out according to JB/T4709-92 "Steel Pressure Vessel Welding Procedure", and the radio graphic inspection conforms to the third level of JB4730-94.

Design parameters:

Hot water tank Design pressure: 0.35MPA Working pressure: <0.3MPA

Design temperature: 147 ° C Operating temperature: < 135 ° C

Sterilization tank Design pressure: 0.35MPA Working pressure: <0.3MPA

Design temperature: 147 ° C Operating temperature: < 135 ° C

Main technical specifications:

1) Material: SUS304 stainless steel.

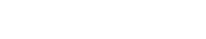

2) One tray one, one hot water tank, one sterilization pots, that is, the hot water tank is used to store the preheated water when the first work of each shift and the hot water after the sterilization is recovered for reuse.

3) Steam heating, automatic temperature control and random adjustment between normal temperature and 135 °C.

4) The pressure in the sterilizer is automatically adjustable according to the temperature, especially when the sterilization is finished. When cooling, the device has an automatic pressure compensation function.

5) PLC touch screen control memory dozens of process programs are easy and simple to operate.

6) The sterilization pot is equipped with a safety protection device, and the pot door cannot be opened before the pressure in the pot is completely discharged.

7) The water inlet type sterilization pot adopts the upper and lower water inlet mode. When the sterilization, the hot water in the pot is from top to bottom, the steam is from bottom to top, and the sterilization temperature is evenly distributed.

Terms and Conditions

Price Validity

Our price are valid for a period of 20days. After this term,we reserve the right to revise our price.

Terms of delivery

40-90days after receipt of down payment and all technical and commercial details have been agreed upon.

Price Basis

FOB Shanghai including seaworthy packing, according to INCOTERMS 2000

Terms of Payment

Payment term: 40% down payment by telegraphic transfer within 7days upon the signing of the contract, the balance paid by telegraphic transfer or LC prior to shipping date from our company

After sale service

The equipment certificates will be distributed to our customer as well as the users' instruction booklet, which ensures the correct and safe installation.

Our professional engineer staffs will guide the installation procedure and also useful training programs.

Guarantee

JIMEI guarantees the aforementioned products against possible defects of materials and /or workmanship for a period of 12 months beginning from the date of installation.In particular, JIMEI will repair and /or substitute the defective parts at its own expense,provided the purchaser gives timely written notice within 15 days from the discovery of the defect,and however within the aforesaid maximum 12months’ period.

The hot water tank and the sterilization tank are the first pressure vessels, which are manufactured, tested and accepted according to the national standard GB150-1998 "Steel Pressure Vessel" and the former Ministry of Labor "Pressure Vessel Safety Technology Supervision Regulations".

Welding is carried out according to JB/T4709-92 "Steel Pressure Vessel Welding Procedure", and the radio graphic inspection conforms to the third level of JB4730-94.

Design parameters:

Hot water tank Design pressure: 0.35MPA Working pressure: <0.3MPA

Design temperature: 147 ° C Operating temperature: < 135 ° C

Sterilization tank Design pressure: 0.35MPA Working pressure: <0.3MPA

Design temperature: 147 ° C Operating temperature: < 135 ° C

Main technical specifications:

1) Material: SUS304 stainless steel.

2) One tray one, one hot water tank, one sterilization pots, that is, the hot water tank is used to store the preheated water when the first work of each shift and the hot water after the sterilization is recovered for reuse.

3) Steam heating, automatic temperature control and random adjustment between normal temperature and 135 °C.

4) The pressure in the sterilizer is automatically adjustable according to the temperature, especially when the sterilization is finished. When cooling, the device has an automatic pressure compensation function.

5) PLC touch screen control memory dozens of process programs are easy and simple to operate.

6) The sterilization pot is equipped with a safety protection device, and the pot door cannot be opened before the pressure in the pot is completely discharged.

7) The water inlet type sterilization pot adopts the upper and lower water inlet mode. When the sterilization, the hot water in the pot is from top to bottom, the steam is from bottom to top, and the sterilization temperature is evenly distributed.

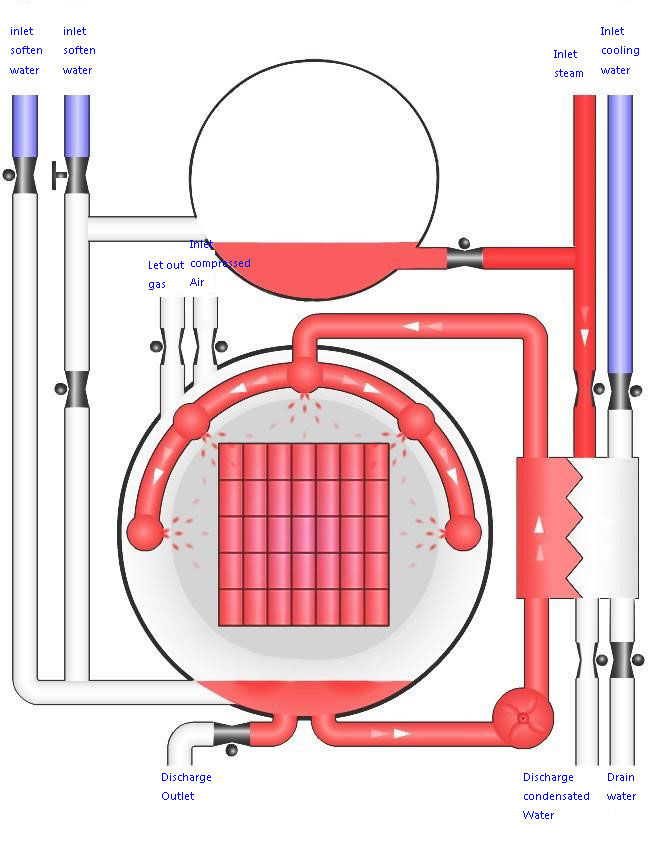

| Name/unit/model | RSS-720 |

| Diameter of sterilizing pot | 1100mm |

| Length of sterilizing pot | 2400mm |

| Number of sterilizing basket | 2 |

| Work puessure | ≥0.35mpa |

| Sterilizing temperature | ≤135℃ |

| Heating steam pressure | ≥0.6mpa |

| Hot water recycling spraying volume | 15t/h |

| Condesed air pressure | 0.7map |

| Size | 3000×2200×3600mm |

Terms and Conditions

Price Validity

Our price are valid for a period of 20days. After this term,we reserve the right to revise our price.

Terms of delivery

40-90days after receipt of down payment and all technical and commercial details have been agreed upon.

Price Basis

FOB Shanghai including seaworthy packing, according to INCOTERMS 2000

Terms of Payment

Payment term: 40% down payment by telegraphic transfer within 7days upon the signing of the contract, the balance paid by telegraphic transfer or LC prior to shipping date from our company

After sale service

The equipment certificates will be distributed to our customer as well as the users' instruction booklet, which ensures the correct and safe installation.

Our professional engineer staffs will guide the installation procedure and also useful training programs.

Guarantee

JIMEI guarantees the aforementioned products against possible defects of materials and /or workmanship for a period of 12 months beginning from the date of installation.In particular, JIMEI will repair and /or substitute the defective parts at its own expense,provided the purchaser gives timely written notice within 15 days from the discovery of the defect,and however within the aforesaid maximum 12months’ period.

Related Products

Hot Water Steam Sterilization Tunnel Machine

Service