Dairy Milk Factory

| Product | Picture | Volume | Production |

| UHT Milk Production Line |

|

2T/D–500T/D | Pasteurized whole milk,Pasteurized skimmed milk,Pasteurized flavor milk |

| Fresh Milk Production Line Plant |

|

2T/D–500T/D | Pasteurized milk,skimmed milk,flavor milk |

| Yoghurt Production Line |

|

2T/D–500T/D | Stirred yoghurt, Set yoghurt, Drinking yoghurt,etc |

| Milk Powder Production line |

|

1.5T/D–100T/D | Whole milk powder Sweet milk powder Skimmed milk powder Infant milk powder Formulated milk powder |

| UHT milk Sterilization machine |

|

2000 | / |

| Milk pasteurizer(plate type) |

|

1 | / |

| Condensed Milk Production Line |

|

from 5 tons/d up to 100 tons/d | Sweetened condensed milk |

| Aseptic Plastic pouch filling packing machine(ESL) |

|

8000 p/h (200ml) | WJB-2D |

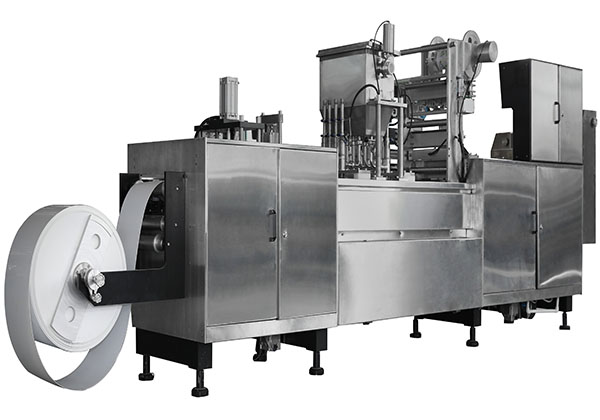

| Plastic cups forming-filling-sealing machine |

|

6000-12000cups | / |

| PET Plastic bottle washing filling capping machine 3 in 1 |

|

3000-18000 | / |

| PP/PE bottle washing filling Aluminum film sealing capping machine |

|

500mL /3000-10000BPH | / |

| Cheese Processing Machine |

|

100Liter to 10000Liter | Cheese |

UHT Milk Production Line

UHT Milk Production Line

With a product that can be stored for long periods without spoiling and with no need for refrigeration, there are many advantages for both the producer, the retailer and the consumer. This includes expensive products such as cream, desserts and sauces. In a modern UHT plant (Ultra High Temperature) the milk is pumped through a closed system. On the way it is preheated, highly heat treated, homogenized, ultra highly heat treated, cooled and packed aseptically. Low acid (pH above 4.5 – for milk more than pH 6.5) liquid products are usually treated at 135 – 150C for a few seconds holding, by either indirect heating or direct steam injection or infusion. High acid (pH below 4.5) products such as juice are normally heated at 90 – 95C for 15 – 30 seconds holding. All parts of the system downstream of the actual highly heating section are of aseptic design to eliminate the risk of reinfection, include aseptic packaging in packages protecting the product against light and atmospheric oxygen. Ambient storage is normal

Fresh Milk Production Line Plant

Fresh Milk Production Line Plant

The Production line produce several types of pasteurized milk products, i.e. whole milk, skimmed milk and standardized milk of various fat contents. First the milk is preheated and standardised by in line milk fat standardisation system. The purpose of standardisation is to give the milk a defined, guaranteed fat content. Common values are 1.5% for low fat milk and 3% for regular grade milk, fat contents as low as 0.1 and 0.5 % is skimmilk.

Then the standardised milk is homogenised. The purpose of homogenisation is to disintegrate or finely distribute the fat globules in the milk in order to reduce creaming. Homogenisation may be total or partial. Partial homogenisation is a more economical solution, because a smaller homogeniser can be used.

Yoghurt Production Line

Yoghurt Production Line

The pretreatment of the milk is the same, regardless of whether set or stirred yoghurt is to be produced. It includes standardization of the fat and dry matter contents, heat treatment and homogenization. It is assumed that the milk has been standardized to the required fat content before entering the line and standardization of the dry matter content takes place in an evaporator in the process line. If the dry matter content is adjusted by addition of milk powder, the equipment used is similar to that described under “Recombined milk”. Any additives, such as stabilizers, vitamins, etc., can be metered into the milk before the heat treatment. When the yoghurt milk has been pretreated and cooled to inoculation temperature, the procedure for further treatment depends on whether set, stirred, drink, frozen or concentrated yoghurt is to be produced.

Milk Powder Production line

Milk Powder Production line

The milk fat content is standardised in a direct standardisation system. Standardised milk used for producing whole milk powder is not normally homogenized.

In the production of dried whole milk the heat treatment must be so intense that the lipases will also be inactivated. This normally involves high-temperature pasteursation to a negative peroxidase test.

Falling-film evaporators are generally used for concentration, which is carried out in two or more stages to a DS content of 45 – 55%.

Condensed Milk Production Line

Condensed Milk Production Line

Figure 16.4 below shows a process line for sweetened condensed milk manufactured from fresh milk. Before evaporation, the fat and solids-non-fat values of the milk have been standardised to predetermined. The milk has also been heat treated to destroy micro-organisms and enzymes which could cause problems and to stabilise the protein complex. Heat treatment is also important to the development of product viscosity during storage, and is particularly important in the case of sweetened condensed milk. The addition of sugar is a key step in the manufacture of sweetened condensed milk, as the shelf life of the product depends on its osmotic pressure being sufficiently high. A sugar content of at least 62.5% in the aqueous phase is required.

UHT milk Sterilization machine

UHT milk Sterilization machine

Automatic tubular UHT unit is suitable for heating and cooling of the stainless steel non-corrosive liquids. The unit is suitable for the sterilization of heat-sensitive liquid materials such as milk, fruit juice, beverages, soy sauce, soy milk, wine, popsicles and ice cream syrup can also be used for the sterilization of liquid drug material, both to ensure complete sterilization, but also to protect the nutrients without loss, the effect is very significant. It can be used with any aseptic filling equipment for continuous production, to produce a shelf life of up to 3 to 6 months.

Milk pasteurizer(plate type)

Milk pasteurizer(plate type)

It fits to heat, sterilize, keep warm, and cool the heat sensitive liquid such as the fresh milk, beverage and juice, wine. This machine is of high recycle, energy saving, and reducing cost, compact constructure, simple operation, and convenient maintain.

Controlling methods: semi-automatically, fully automatically(PLC control, touching view)

Main fittings: material pump, balance tank hot water system, Temp-erature control and tape recorder, and electric, controlling

PP/PE bottle washing filling Aluminum film sealing capping machine

PP/PE bottle washing filling Aluminum film sealing capping machine

This machine is the introduction of foreign technology, the set of automatic control filling, aluminum foil lid of cover sealing, filling sealing machine is equal to the integration plastic bottles. Widely used in food packaging especially for all kinds of pharmaceutical packaging block dairy packaging is a upgrade ideal equipment, with accurate quantitative filling and can eliminate foam, sealing high yield reasonable use double inclined blunt system covering technology, greatly improving the aluminum foil the utilization rate of membrane, mechanical and electrical lift the design class driving more stable operation. An important part of this equipment imported components, electrical components: snyder, PLC man-machine interface touch screen: Siemens.

Plastic cups forming-filling-sealing machine

Plastic cups forming-filling-sealing machine

Suitable for all kinds of yogurt, milk, beverages, butter, cheese, condiments, ice cream and other materials packaging, production from 3000 cups / hour to 6000 cups / hour, automatic molding plastic cup forming, filling, sealing, date printing, Die-cutting and product delivery. The main configuration of the device servo drive, programmable logic control, human-machine interface, temperature control, optoelectronics, pneumatic lubrication control systems are used internationally renowned brands. The series of equipment with cup, cup, butter, cheese and other functions of the models, is a modern enterprise high-quality high-performance, low-power fully automated production equipment.

Aseptic Plastic pouch filling packing machine(ESL)

Aseptic Plastic pouch filling packing machine(ESL)

Equipment for a variety of fresh milk, yogurt, milk flavor, soy milk, fruit juice and other sterile packaging materials, automatic plastic bag sterilization, molding, aseptic filling, sealing and finished product delivery. The series of equipment can be applied to a variety of composite plastic film and aluminum, paper, plastic composite packaging materials. Equipment are the main components of international brands, stable operation, high sterilization efficiency, low energy consumption, is the first choice for the production of sterile long-lasting equipment.

PET Plastic bottle washing filling capping machine 3 in 1

PET Plastic bottle washing filling capping machine 3 in 1

The series equipment is used in hot filling and sealing of green tea, black tea, wulong tea and fruit juice.The machine integrates washing , filling, capping together.The design is scientific and reasonable.Its appearance is beautiful.Its operation and maintenance is convenient.It is good eauipment for choosing hot drink filling machine.

Cheese Processing Machine

Cheese Processing Machine

This cheese vat consist of a triple-walled, insulated, oblong or round stainless steel vat with an overhead stirring machine.The stirring mechanism of oblong vat is driven by two motors: one for longitudinal move and one for the rotating motion.

Dairy Milk Factory

Service