Aseptic Pouch Filling Machine(of fresh milk, yogurt, soy milk, fruit juice etc)

Home > Machinery > Milk Juice Filling Packaging Machine

> Aseptic Pouch Filling Machine(of fresh milk, yogurt, soy milk, fruit juice etc)

Aseptic Pouch Filling Machine(of fresh milk, yogurt, soy milk, fruit juice etc)

Purpose of equipment

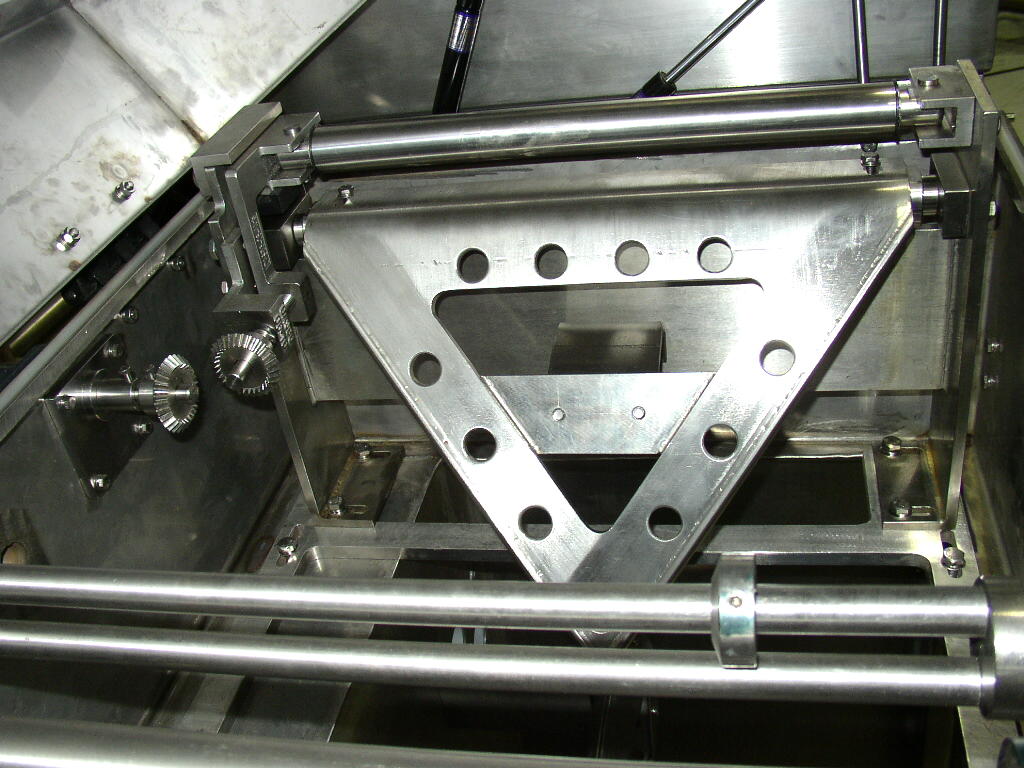

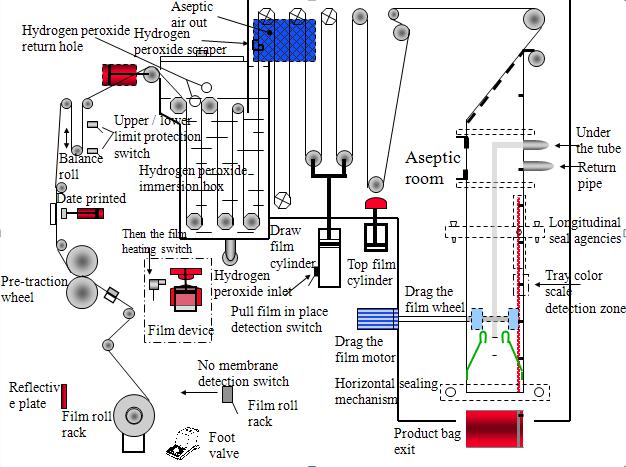

Equipment for a variety of fresh milk, yogurt, milk flavor, soy milk, fruit juice and other sterile packaging materials, automatic plastic bag sterilization, molding, aseptic filling, sealing and finished product delivery. The series of equipment can be applied to a variety of composite plastic film and aluminum, paper, plastic composite packaging materials. Equipment are the main components of international brands, stable operation, high sterilization efficiency, low energy consumption, is the first choice for the production of sterile long-lasting equipment.

The advanced two-sided free-standing aseptic bins, as well as the bag forming and filling system design, can simultaneously produce two different specifications of products, or carry out unilateral independent operation.

The dragging of packaging materials adopts three-stage fixed-length traction technology, adopts servo drive and photoelectric positioning, precise traction length, easy deformation of packaging materials, and is suitable for the production of various sizes of products.

The packaging material is soaked and sterilized by W-type movement in the H2O2 warehouse and dried through aseptic hot air to ensure the sterilization effect of the packaging material.

Sterile warehouse using H2O2 spray sterilization, high-intensity UV sterilization and sterile air replacement technology to ensure that the aseptic chamber sterile state is constant.

Sealing and cutting system driven by a servo motor, stable operation, high precision, fully ensure the finished sealing effect.

Through continuous liquid level controller and digital positioning valve control cylinder constant liquid level, the use of stepper motor diaphragm constant flow control of continuous filling to ensure accurate filling.

The latest single-station two-step sealing device (patented technology), to achieve a single station step by step heat sealing and slitting functions for a variety of aluminum, paper and plastic composite packaging materials, greatly extended The effective shelf life of the finished product.

Equipment integrated CIP and SIP systems ensure that piping and valves in contact with the material are sterile during production.

Specifications and configuration checklist

Terms and Conditions

Price Validity

Our price are valid for a period of 1 month. After this term,we reserve the right to revise our price.

Terms of delivery

40-90days after receipt of down payment and all technical and commercial details have been agreed upon.

Price Basis

FOB Shanghai including seaworthy packing, according to INCOTERMS 2000

Terms of Payment

Payment term: 30% down payment by telegraphic transfer within 7days upon the signing of the contract, the balance paid by telegraphic transfer or LC prior to shipping date from our company

After sale service

The equipment certificates will be distributed to our customer as well as the users' instruction booklet, which ensures the correct and safe installation.

Our professional engineer staffs will guide the installation procedure and also useful training programs.

Guarantee

JIMEI guarantees the aforementioned products against possible defects of materials and /or workmanship for a period of 12 months beginning from the date of installation.In particular, JIMEI will repair and /or substitute the defective parts at its own expense,provided the purchaser gives timely written notice within 15 days from the discovery of the defect,and however within the aforesaid maximum 12months’ period.

Equipment for a variety of fresh milk, yogurt, milk flavor, soy milk, fruit juice and other sterile packaging materials, automatic plastic bag sterilization, molding, aseptic filling, sealing and finished product delivery. The series of equipment can be applied to a variety of composite plastic film and aluminum, paper, plastic composite packaging materials. Equipment are the main components of international brands, stable operation, high sterilization efficiency, low energy consumption, is the first choice for the production of sterile long-lasting equipment.

The advanced two-sided free-standing aseptic bins, as well as the bag forming and filling system design, can simultaneously produce two different specifications of products, or carry out unilateral independent operation.

The dragging of packaging materials adopts three-stage fixed-length traction technology, adopts servo drive and photoelectric positioning, precise traction length, easy deformation of packaging materials, and is suitable for the production of various sizes of products.

The packaging material is soaked and sterilized by W-type movement in the H2O2 warehouse and dried through aseptic hot air to ensure the sterilization effect of the packaging material.

Sterile warehouse using H2O2 spray sterilization, high-intensity UV sterilization and sterile air replacement technology to ensure that the aseptic chamber sterile state is constant.

Sealing and cutting system driven by a servo motor, stable operation, high precision, fully ensure the finished sealing effect.

Through continuous liquid level controller and digital positioning valve control cylinder constant liquid level, the use of stepper motor diaphragm constant flow control of continuous filling to ensure accurate filling.

The latest single-station two-step sealing device (patented technology), to achieve a single station step by step heat sealing and slitting functions for a variety of aluminum, paper and plastic composite packaging materials, greatly extended The effective shelf life of the finished product.

Equipment integrated CIP and SIP systems ensure that piping and valves in contact with the material are sterile during production.

-

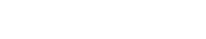

- Film tube triangle forming device: Through the triangle forming plate Film folded. Membrane corrective equipment Set and adjust operation: pass Adjust the film left and right tension Size, correct partial membrane; pass Touch the adjustment button on the touch screen Adjust.

-

- Longitudinal sealing mechanism: through the front and back vertical sealing device coordination action, so that the film folded double membrane tube.

-

-

Specifications and configuration checklist

|

Model |

DASB-6 |

DASB-6D |

DASB-8 |

DASB-8L |

DASB-16L |

|

Yield |

6000 p/h (250ml) |

6000 p/h (500ml) |

8400 p/h (250ml) |

8000 p/h (100ml) |

16000 p/h (100ml) |

|

Capacity |

100-500 (ml) |

500-1000 (ml) |

100-500 (ml) |

100-500 (ml) |

100-500 (ml) |

|

Packaged form |

Pillow strap、Vertical band |

Pillow strap |

Pillow strap、Vertical band |

Pillow strap |

Pillow strap |

|

Packing material |

Multilayer composite plastic film |

Aluminum-plastic paper-plastic composite film |

|||

|

Ultra-clean version |

● |

● |

● |

● |

● |

|

Clean version |

● |

● |

● |

● |

● |

Terms and Conditions

Price Validity

Our price are valid for a period of 1 month. After this term,we reserve the right to revise our price.

Terms of delivery

40-90days after receipt of down payment and all technical and commercial details have been agreed upon.

Price Basis

FOB Shanghai including seaworthy packing, according to INCOTERMS 2000

Terms of Payment

Payment term: 30% down payment by telegraphic transfer within 7days upon the signing of the contract, the balance paid by telegraphic transfer or LC prior to shipping date from our company

After sale service

The equipment certificates will be distributed to our customer as well as the users' instruction booklet, which ensures the correct and safe installation.

Our professional engineer staffs will guide the installation procedure and also useful training programs.

Guarantee

JIMEI guarantees the aforementioned products against possible defects of materials and /or workmanship for a period of 12 months beginning from the date of installation.In particular, JIMEI will repair and /or substitute the defective parts at its own expense,provided the purchaser gives timely written notice within 15 days from the discovery of the defect,and however within the aforesaid maximum 12months’ period.

Related Products

High Speed Carton Type Packin

JMB-6000 aseptic carton filling machine 200ML A:Device characterization The main features are: disposable auto-complete feed, sterilization, box making, filling, forming, sealing action, the molding of composite materia...

Learn more >>

Aseptic Plastic Pouch Filling

Purpose of equipment Equipment for a variety of fresh milk, yogurt, milk flavor, soy milk, fruit juice and other sterile packaging materials, automatic plastic bag sterilization, molding, aseptic filling, sealing and fini...

Learn more >>

Plastic stand up pouch fillin

Product description : This machine is suitable for packaging jelly,soy milk, yogurt, mineral water, juice, ice cream, edible oil, seasoning, scour and so on. We also can add some function according customers. This machi...

Learn more >>

Plastic cups forming-filling-

Suitable for all kinds of yogurt, milk, beverages, butter, cheese, condiments, ice cream and other materials packaging, production from 3000 cups / hour to 6000 cups / hour, automatic molding plastic cup forming, filling,...

Learn more >>

PP/PE bottle washing filling

Product synopsis : This machine is the introduction of foreign technology, the set of automatic control filling, aluminum foil lid of cover sealing, filling sealing machine is equal to the integration plastic bottles. Wid...

Learn more >>

Normal pressure hot filling m

Description The series equipment is used in hot filling and sealing of green tea, black tea, wulong tea and fruit juice.The machine integrates washing , filling, capping together.The design is scientific and reasonable.It...

Learn more >>

Isobaric filling machine 3-in

Description The series of machines are the integrated rinsig. filling and capping machine, suitable for filling various PET bottled carbonatd beverages. Technical Parameter Model CGF14-12-5 CGF18-18-6 CGF24-24-8 CGF32-32-...

Learn more >>

Glass bottle filling machiner

Washing head: Filling head: Capping head: Purpose of equipment Introduction to glass bottle filling machinery: The glass bottle filling machine integrates three functions of rinsing, filling and sealing, and is suitable f...

Learn more >>

Automatic 3 in 1 Water Fillin

Purpose of equipment Fostream3 in 1 filling machineis used in washing, filling and sealing all kinds ofno gas contained liquid, such as Pure Water, Fruit Juice, Carbonated Beverage.The line has features of unique design, ...

Learn more >>

Milk Juice Filling Packaging Machine

Service